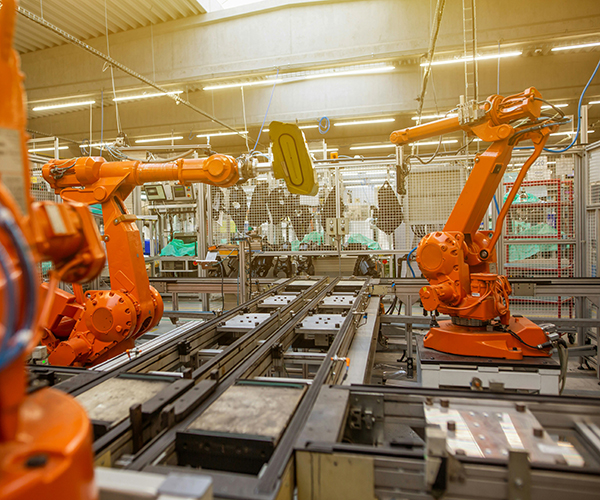

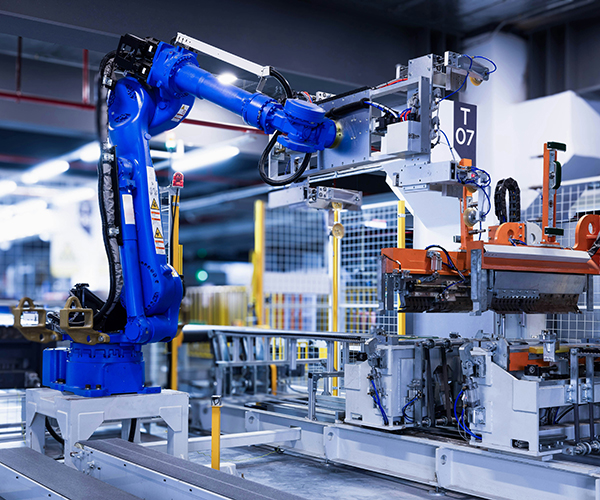

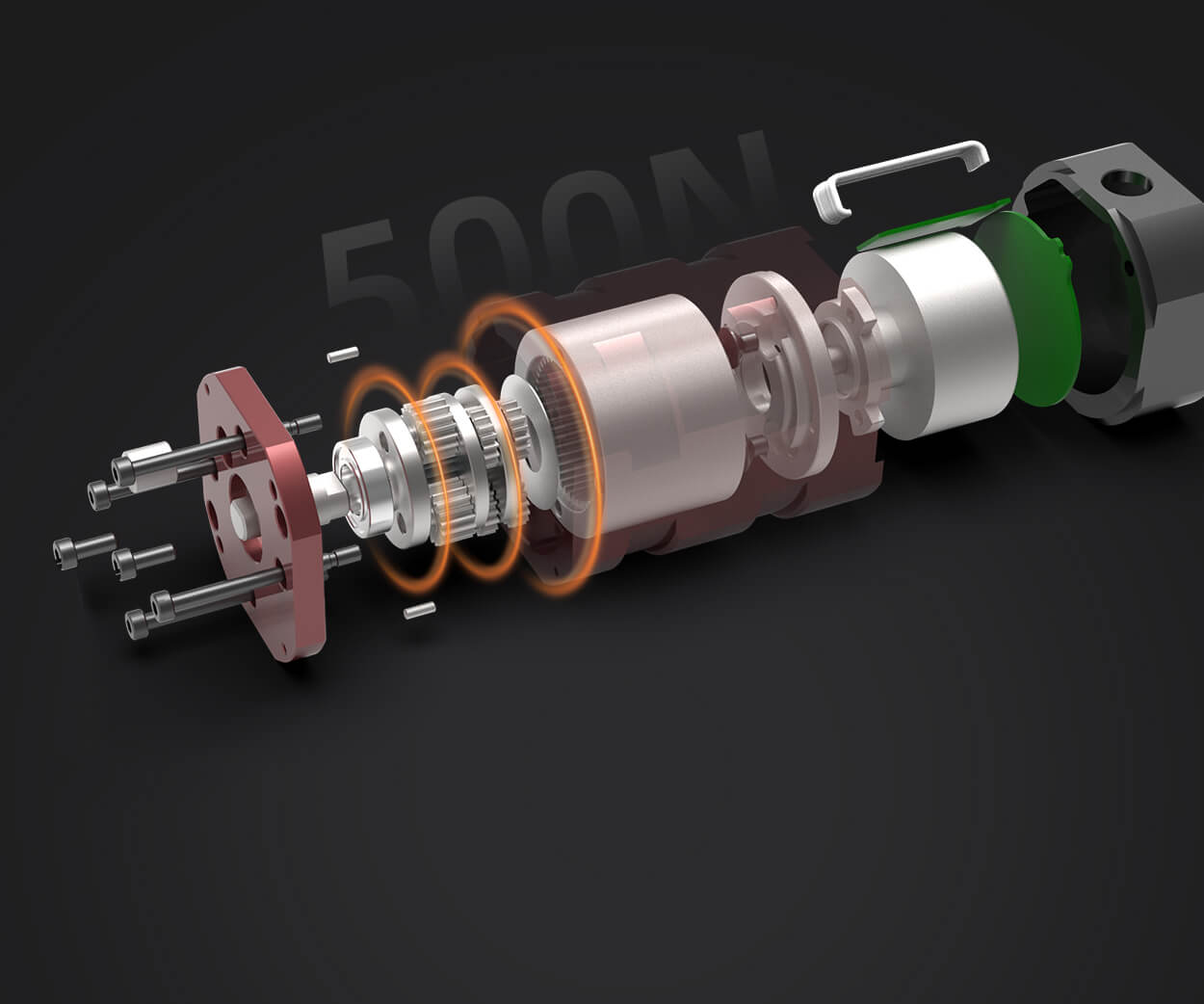

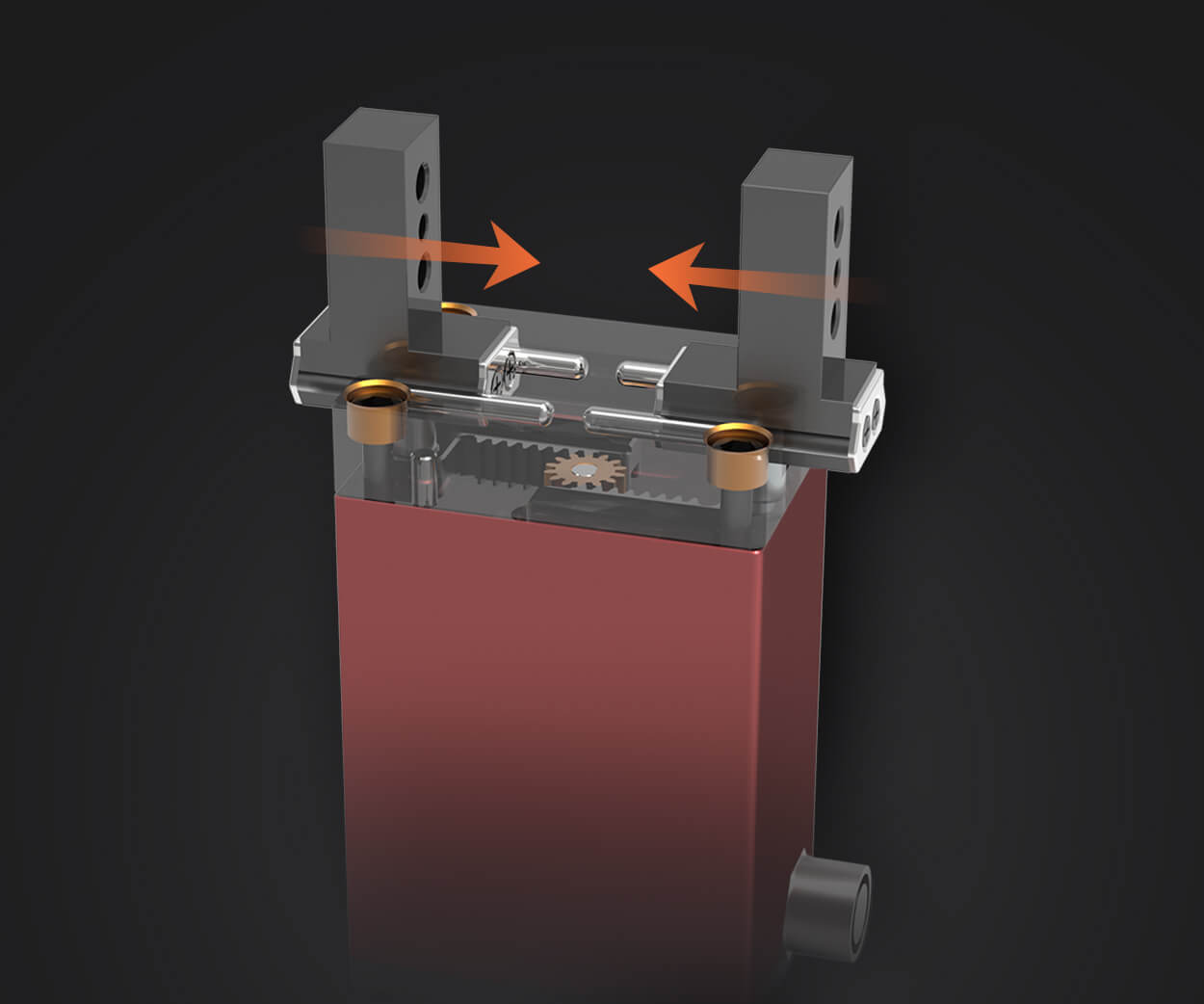

Comprehensive Drive Products Series

Reliable smart cabin domain drive modules, validated through multiple rounds of "Automotive-grade" testing, ensuring safe and comfortable journeys for vehicle occupants.