The hum of a factory floor, the graceful arc of a robotic arm, the seamless adjustment of a satellite’s solar panel—these feats of engineering share a silent hero: the DC servo motor. While often overlooked, these compact powerhouses are the unsung arcts of precision in industries ranging from manufacturing to space exploration. Let’s pull back the curtain on how these motors shape the technology we rely on daily.

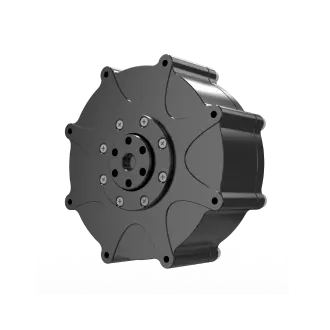

The Anatomy of Precision

At its core, a DC servo motor is a marriage of simplicity and sophistication. Unlike standard motors, which spin freely once powered, servo motors integrate feedback mechanisms—like encoders or resolvers—to enable real-time adjustments. This closed-loop system allows them to control speed, torque, and position with surgical accuracy. Imagine a concert pianist’s fingers: every keystroke is deliberate, every movement calibrated. DC servo motors operate with that same finesse, translating electrical signals into mechanical motion that’s both dynamic and exact.

Robotics: Where Machines Mimic Life

In robotics, DC servo motors are the muscles and nerves of artificial beings. Take collaborative robots (cobots) working alongside humans on assembly lines. A cobot’s ability to lift a fragile circuit board or weld a car chassis hinges on servo motors that adjust torque instantaneously. Too much force? The component breaks. Too little? The weld fails. Servo motors strike the balance, enabling robots to handle tasks with human-like dexterity.

But it’s not just industrial robots. Prosthetic limbs powered by servo motors restore mobility to amputees by interpreting neural signals into fluid motion. Boston Dynamics’ Spot robot, which navigates uneven terrain with eerie grace, relies on servo-driven joints to adapt to obstacles in real time. These motors don’t just move parts—they breathe life into machines.

Manufacturing: The Backbone of Efficiency

Modern factories are symphonies of motion, and DC servo motors are the conductors. In CNC machines, they guide cutting tools along micrometer-perfect paths, carving aerospace components from titanium blocks. Packaging lines use servo-driven actuators to position products at speeds of 200 items per minute—without missing a beat. Even 3D printers leverage their precision, layering materials atom by atom to create everything from dental implants to rocket engine parts.

The shift toward Industry 4.0 has only amplified their role. Smart factories employ servo motors with IoT connectivity, allowing engineers to monitor performance remotely. Predictive maintenance algorithms analyze motor feedback to foresee failures before they occur, slashing downtime. In a world where margins are measured in microns and milliseconds, DC servo motors are the ultimate competitive edge.

From Lab to Living Room

Beyond heavy industry, these motors quietly enhance everyday life. Camera gimbals use servo stabilization to turn shaky handheld footage into cinematic gold. Home automation systems rely on them to adjust smart blinds or position solar panels for optimal energy harvest. Even your coffee maker’s burr grinder likely uses a micro servo to achieve the perfect grind consistency.

The medical field is another frontier. Surgical robots like the da Vinci system employ servo motors to translate a surgeon’s hand movements into precise incisions, minimizing invasiveness. Meanwhile, lab automation systems use them to handle delicate tasks like pipetting nanoliters of DNA samples—work too exacting for human hands.

As Part 1 concludes, it’s clear that DC servo motors are the invisible enablers of progress. But their story doesn’t end here. In Part 2, we’ll explore how they’re propelling humanity into the skies, revolutionizing renewable energy, and redefining what’s possible in the 21st century.

If Part 1 revealed DC servo motors as the workhorses of terrestrial innovation, Part 2 launches them into the stratosphere—literally. From wind turbines harnessing gale-force winds to satellites aligning with distant stars, these motors are engineering’s answer to the question: How do we control the uncontrollable?

Aerospace: Mastering the Final Frontier

Spacecraft are monuments to precision, and DC servo motors are their guardians. Consider the James Webb Space Telescope: its mirrors must align within nanometers to capture light from the dawn of the universe. Servo motors adjust each segment with zero room for error, compensating for temperature fluctuations and cosmic vibrations. Closer to Earth, satellites use servo-driven reaction wheels to maintain orientation, ensuring communication signals stay locked on target.

Even re-entry relies on servo precision. The SpaceX Falcon 9’s grid fins—controlled by ruggedized servo actuators—steer the rocket through Earth’s atmosphere at hypersonic speeds. One miscalculation, and the booster misses its landing pad. But with servo motors, SpaceX nails landings so consistently it’s become routine—a testament to their reliability under extreme stress.

Renewable Energy: Harnessing Nature’s Fury

Wind turbines face a paradox: they need strong winds to generate power but must survive storms that could destroy them. Enter pitch control systems driven by DC servo motors. When winds exceed safe limits, servos adjust turbine blade angles within seconds, reducing lift and preventing catastrophic failure. Offshore turbines, battered by saltwater and hurricanes, depend on corrosion-resistant servo systems to operate maintenance-free for decades.

Solar energy also leans on servo innovation. Dual-axis solar trackers use motors to follow the sun’s path across the sky, boosting energy harvest by up to 45%. In deserts, where sandstorms threaten to scuttle panels, self-cleaning systems employ servo-driven brushes that sweep surfaces without damaging photovoltaic cells. It’s a delicate dance between power generation and preservation—orchestrated by servo motors.

The Electric Vehicle Revolution

Electric vehicles (EVs) are redefining mobility, and DC servo motors are at the wheel. Steering systems once reliant on hydraulic pumps now use servo-driven electronic power steering (EPS), which adjusts assist levels based on speed. At low speeds, steering feels light for parking; at highway velocities, it firms up for stability. Regenerative braking systems, another servo application, recover kinetic energy during deceleration, funneling it back into the battery.

Even charging infrastructure depends on servos. Robotic charging arms, guided by servo motors, plug into EVs with millimeter accuracy—critical for autonomous fleets where no human is present to adjust misaligned connectors. As EVs evolve into self-driving hubs, servo motors will remain the linchpin of their electromechanical nervous system.

Tomorrow’s Servo: Smaller, Smarter, Stronger

The future of DC servo motors lies in miniaturization and AI integration. Researchers are developing piezoelectric servo motors smaller than a grain of rice for medical nanobots capable of clearing arterial blockages. Meanwhile, AI algorithms trained on motor feedback data can predict wear patterns, optimizing performance in real time.

In agriculture, servo-driven drones will plant seeds and apply fertilizers with pinpoint accuracy, revolutionizing precision farming. Quantum computing labs might use cryogenic servo motors to position qubits in supercooled environments, where traditional actuators fail.

Conclusion: The Quiet Revolution

DC servo motors are more than components—they’re catalysts for innovation. Whether steering rockets, empowering surgeons, or brewing your morning espresso, they exemplify humanity’s quest to shape the physical world with exactitude. As technology hurtles forward, these motors will remain indispensable, turning the impossible into the everyday. The next time you marvel at a machine’s precision, remember: behind every graceful motion, there’s a servo motor whispering, “I’ve got this.”